From Lab to Market Faster: Next‑Gen Aseptic Fill & Finish

Comprehensive Fill and Finish Services for liquid injectables in vials, pre-filled syringes or cartridges.

At White Raven, we provide state-of-the-art fill-and-finish services tailored to your manufacturing needs meeting the standards of the pharmaceutical industry.

Next‑gen fill & finish solutions

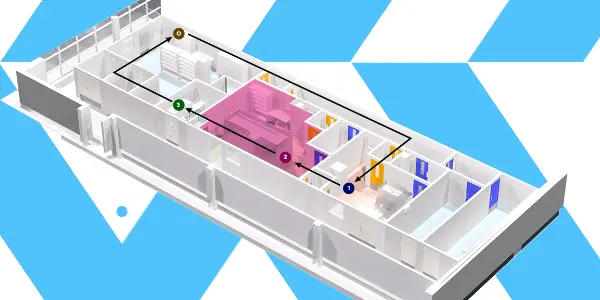

White Raven Aseptic Filling Workcell - Cytiva SA25

Why it’s different:

Our Aseptic Filling Workcell provides a diverse range of filling services, with the capability to work with mixing volumes as low as 100mL, and up to 20L.

Flexible volumes:

50 mL → 20 L, from small to medium batches.

Scalable output:

100 → 20,000 units per batch.

Zero human risk:

Fully robotic, no glove ports, contamination risk minimized.

Multi-format capability:

Vials, syringes, cartridges, 0.2 – 50 mL. Quick changeovers between batches and container types.

The SA25 allows for additional flexibility in terms of a quick changeover between batches, projects, and/or containers.

The White Raven Advantage

Short turnaround between batches

Agile production to scale with your project needs

Coverage of a wide range of liquid injectables

Container types:

Polymer & glass vials (2–50 mL)

Syringes (0.5–20 mL)

Cartridges (1.5–20 mL)

Product care:

Low product loss

High-efficiency N₂/CO₂ gassing

Minimized environmental contamination

Why Innovators Choose White Raven

Seamless End-to-End: Fill, finish, and delivery

All under one roof

Fast & Flexible:

Robotic precision with batch release in as little as 4 months.

Safe & Compliant:

True Annex 1 compliance at every step.

Future-Ready:

Agile technology and processes built for innovators who won't wait.

Think of us as your "fast-track" CDMO

From Concept → Clinic → Market

We don't just fill vials...we accelerate innovation.

Your project benefits from:

- Predictable timelines for small-to-medium batches

- Reduced contamination risk through automation

- Flexibility to pivot as your program evolves