Unmatched Formulation

Capabilities

Leading Pharmaceutical Formulation Services.

Every formulation is engineered with intent. Every process is designed to protect your product.

Whether you require small-batch formulations or mid-scale production, our facility is equipped to handle your needs efficiently.

Precision, Adaptability, and Quality

Key Features

We provide a diverse range of formulation services adapted to small batches, with the capability to work with mixing volumes as low as 50mL, and up to 20L.

Diverse Batch Sizes:

From as low as 50mL to up to 20L, we accommodate a wide range of batch sizes to suit your specific requirements.

Single-Use Systems:

Our single-use approach minimizes the risk of cross-contamination, ensuring product integrity.

Sterile and Non-Sterile Options:

We offer both sterile and non-sterile mixing to meet the varied demands of pharmaceutical development.

Integrated IT Processes:

Our operations are fully integrated with advanced IT systems, reducing the risk of human error and enhancing efficiency.

High Chemical Compatibility:

Our facilities are equipped to handle a broad spectrum of chemicals, supported by an extensive extractable package and minimal particle load.

Possibility to add monitoring probes (pH, conductivity)

Designed for Confidence at Every Step

Specifications & Range

Our single-use systems are purpose-built to reduce cross-contamination risks while accelerating development timelines.

Production Environment

Formulation is performed in a dedicated cleanroom, serving as the first critical stage of our aseptic filling process, ensuring continuity, compliance, and control from the very start.

Download our brochure to learn more

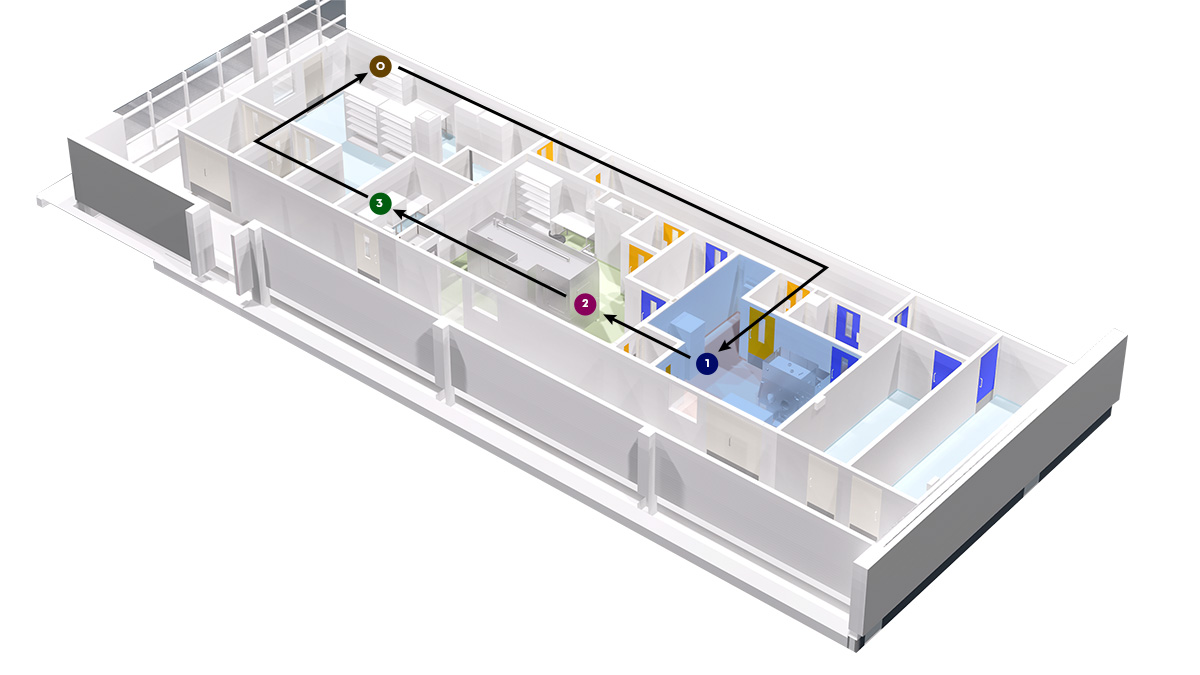

Production Facility

Our dedicated cleanroom for Formulation is the first room of our Aseptic Filling process.

Learn more about our Production Facility