Visual

Inspection

Visual

Inspection

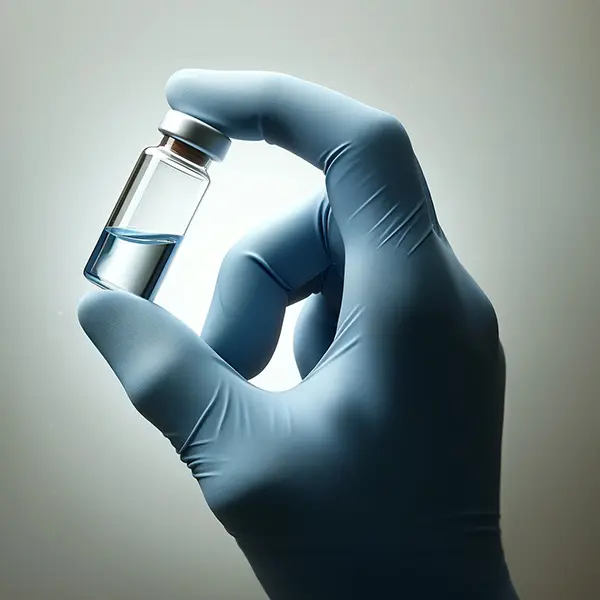

Optimizing Pharmaceutical Integrity with Premier Visual Inspection Services.

Our tailored visual inspection services are designed specifically to verify the quality, and precision of our Fill & Finish services, alongside ensuring that your products are produced safely.

Visual Inspection Excellence

Key Features

Tailored Inspection Processes:

Every product is unique, and so are our inspection strategies. We meticulously adapt our processes to meet the specific requirements of each product, including particle inspection and container integrity checks. Our goal is to ensure that each unit we handle meets your exact specifications.

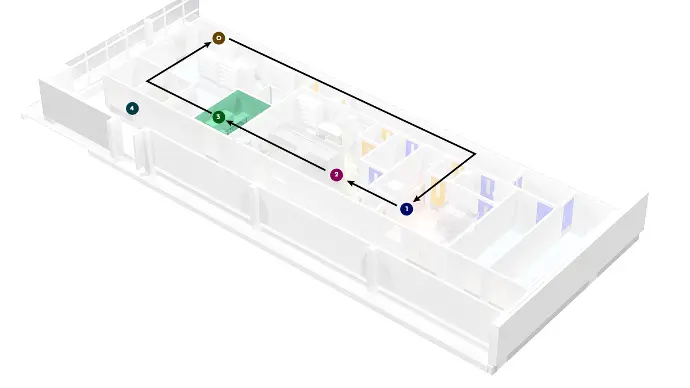

Real-Time Quality Control:

Situated close to the aseptic filling room, our visual inspection room provides seamless quality control. This proximity allows for the immediate identification and segregation of defective units, drastically reducing the risk of contamination or defect spread throughout the batch.

Benefits

Enhanced Product Safety:

By minimizing the risk of contaminants and defects, we ensure the safety and efficacy of injectables, thus protecting both patient health and your brand's reputation.

Regulatory Compliance:

Our manual inspection processes are designed to meet stringent GMP guidelines, helping you maintain regulatory compliance effortlessly.

Customized Support:

We pride ourselves on our ability to adapt our services to meet your product's specific needs, offering unmatched flexibility and responsiveness.

Reduced Risk of Errors:

With expert staff and precise inspection processes, we significantly reduce the risk of errors, ensuring the highest quality output.

Flexibility in Production:

Our manual processes allow for quick adjustments and customization, ideal for managing small batches and special requirements.

Download our brochure to learn more