Project Kickoff

The cleanroom construction project officially kicked off in 2024. The collaborators that will support this project will be COCEPTIO, Jansen Group, and Close HVAC.

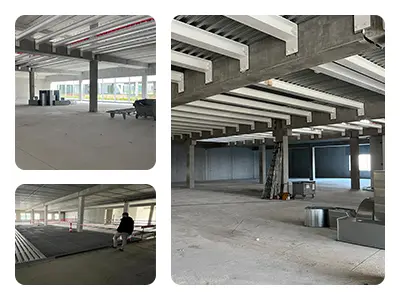

Superstructure Set & Site Preparation

The site preparation involves thorough steps to ensure strict cleanliness standards are met, including clearing and leveling the ground, establishing utility connections, and implementing environmental controls. Additionally, structural modifications, such as reinforced flooring and walls, are in progress to ensure a strong foundation.

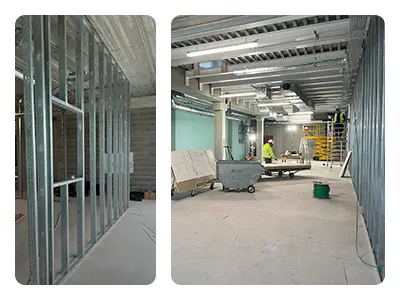

Installation of Peripheral Partitions & Start of Ductwork

The peripheral partitions are now installed, forming the sturdy framework that divides our cleanroom space from the rest. These partitions are made with materials meeting stringent cleanroom standards and are equipped with windows, doors, and pass-throughs for seamless operation and personnel flow.

Building the partitions

The construction team has begun building the partitions inside the manufacturing unit. The ducting on the shop floor and the installation of cable trays are progressing quickly.

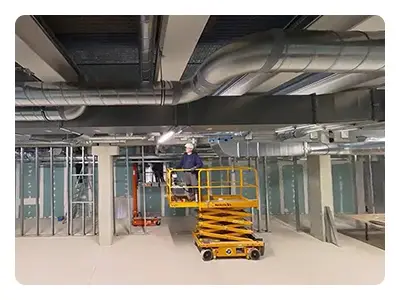

HVAC units delivery

A significant milestone in the project has been reached: the long-awaited HVAC units have been delivered on-site. Contractor teams are now working on rigging the units and preparing the connections to the ducting network. In parallel, electricians have begun pulling power and data cables to the technical area.

Cable trays installations

Significant progress has been made over the past few weeks. Cable trays have been installed, cables have been pulled, and the ducting work is complete.

The supporting frame for the ceiling panels has been fixed onto the partitions, which are nearly finished. The team has even started installing the door frames..

Ceiling installation is complete

The ceiling installation is complete, and the contractor has started installing the HPL finishing panels.

Additionally, the ceiling lights have been installed within the ceiling.

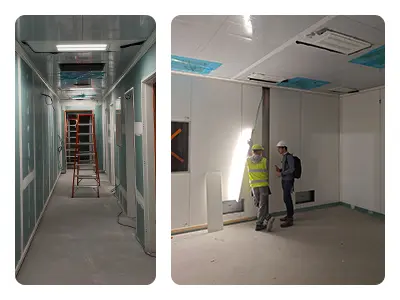

Grade D corridor

Focusing on the warehouse and the Grade D corridor, the rooms are nearly finished.

Preparations for installing the finishing panels have already begun.

Ceilings finished

The partitions and ceilings are now finished, and the rooms are ready for floor installation.

The HVAC grid installation has also begun, and everything is looking great.

The installation of the PVC floor

The installation of the PVC floor and doors has been successfully completed in all the rooms.

It is kindly requested that no questions be directed to Joachim regarding the color of the PVC floors in the formulation and filling room, as this particular artistic touch falls outside his area of responsibility!

Progressing Towards Completion of the Technical Area

A nearly finished technical area, all the equipment has been installed, and testing has started. Also, the SA25 is pristine and clean following the first cleaning with TRU Global Solutions.

Finalization of the wall painting process

Start-up of the SA25 system

Launch of the SA25

Continuation of the SA25 start-up

Preparation of the cleanroom

Our clean room is getting into shape,

meticulous attention being given to final adjustments and details.

Arrival of our new Formulation Isolator

The new isolator that we acquired from Eurobioconcept is now on site,

we are only a few steps away from finalizing our Cleanroom setup.

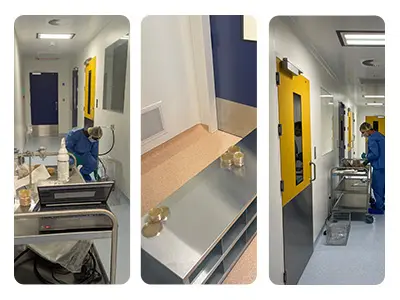

Enhancing Cleanroom Standards

We focus on maintaining the cleanliness of the cleanroom.

From scrubbing the walls to donning our protective gear, every step is vital to maintaining the highest standards of cleanliness and safety.

Performance Qualification (PQ) for Environmental Monitoring (EM)

We conducted the PQ in operations for the EM which has been performed by HeX Group.

The EM PQ activities aim to assess the quality of our environment compared to the classification criteria for each room/grade.

Left picture:

Showing the Grade C gowning in the formulation room

Right picture:

The SteriLAF isolator has been fully installed

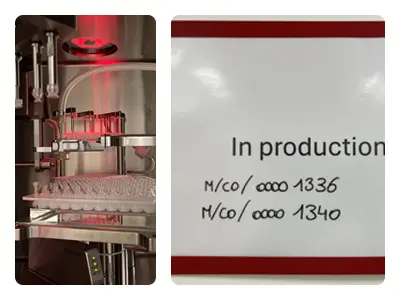

PQ EM

PQ EM (Performance qualification environmental monitoring) of the SA25. Particle counting in activity.

This marks a crucial step forward in our validation process.

PQ EM + DSI

- PQ EM in activity.

- Ongoing decontamination in the Decontamination and Staging isolator (DSI).

- Assembly of a Microbio sampler in the formulation isolator.

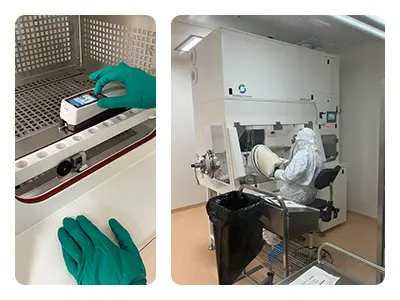

Formulation Isolator Rugosity Testing & PQ EM Sampler Preparation for SA25

- Left picture: Rugosity testing for the formulation isolator.

- Right picture: Preparation of EM samplers to be used for the PQ EM in activity of the SA25.

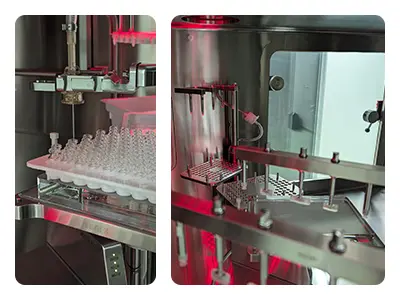

VPHP Testing: SteriLAF Injection Test & Full Load SA25 DSI Decontamination

Left picture:

VPHP testing of our SteriLAF (injection test)

Right picture:

Full load of t e SA25 DSI for VPHP decontamination test

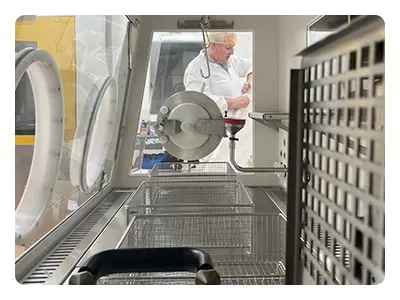

Training Batch Filling - PQ Preparation

Filling of a training batch as we are preparing our PQ

Training batch on the SA25

PQ VPHP of the SteriLAF

Right picture:

Flow path installation on the SA25 (training batch)

Left picture:

Set-up of the sterile filtration and the aseptic filling (training batch)

PQ EM (Performance Qualification - Environmental Monitoring) of the Aseptic filling workcell

PQ (Performance Qualification) VPHP (Bio-Decontamination) of our Formulation Isolator

Start up the filling of an APS

Left picture :

SWAB and flow paths installed on the filling rack

Right picture:

Installation of the flow path in the DDP (Dynamic Peristaltic Pump)

Left picture :

Filling of 2R vials

Right picture:

EM devices assembly for the Aseptic Process Simulation